Fixing the right rear corner 1/2

We got the bus finally in the garage, so the time was right to start with the more serious fixes. In the evening of 29th of November, I started by cutting and drilling out the first panels. Since it was more than clear that the rear right wheel arch panel needs to be replaced, it wasn’t mentally very hard to make the first cuts.

Besides removing the arch panel, some more problems in the area needed my attention:

- The air guide box behind the tail light needs to be fixed

- The floor of the trunk was rusted above the wheelhouse

- The joint between the lower edge of the corner panel and the air guide box was thoroughly corroded

- The lower edge of the corner panel was also thoroughly rusted

- The bottom panel of the corner panel was rusted at the joint

The Corner Panel

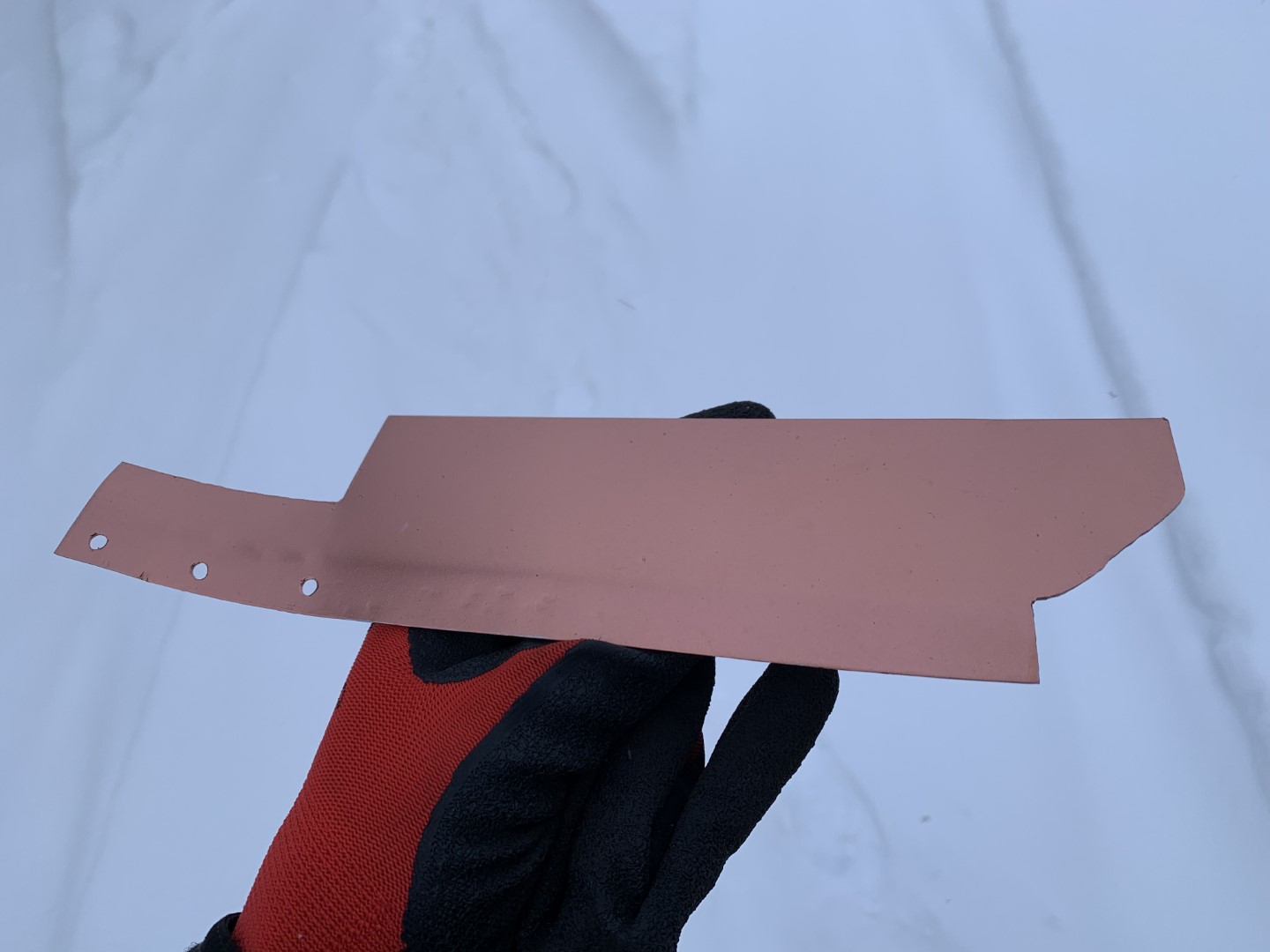

When quite a lot of old and rotten material had been removed, it was time to start shaping and welding new metal to replace the old ones. The first panel to get a new lower edge was the corner panel. I cut the necessary material from a AHSchofield panel ordered from Brickwerks. This panel was made for repairing the bottom section of the rear corner (VW part 251 813 368). I used only the lower edge from that panel, because the replacement panel’s shape was not 100% the same as the original VW panel. However, it was a 1 mm thick piece of metal that was good enough as a source material.

Welding this piece into place was also the very first welding job I had ever done on a car body with a MIG/MAG welding machine. I did practice though on some random pieces of metal first, to get to know the machine better. The welding machine I use is a single phase Telwin inverter with Ar/Co mix gas.

After removing the rear arch panel, I actually got a pleasant surprise. The corner panel itself was in fact in a pretty good shape. Only one tiny edge of the corner needed some patching and the dent and a hole, which were hidden under the filler, needed a bit of fixing.

Air Guide Box

Next up was fixing the air guide box (VW p/n 251 801 560) and filler plate for corner panel (WV p/n 251 813 400). I could’ve ordered a whole new repair panel for air guide box, but as the original panel did not seem to be in a too horrible state yet, I decided to restore the original.

The Floor of the Trunk

It was a little bit surprising how deeply rusted the floor of the trunk was. I believe that the water has been leaking for quite some time through the seal of the trunk hatch and flowed under the sound absorbing mat, where the excessive moisture had done it’s job.

Since it is rather unusual place to be rusted, I didn’t manage to find new replacement panels for this. Thankfully, the members of the Estonian T3 Facebook group, who had donor T3 bodies, helped me out by letting me cut out necessary pieces for replacement.

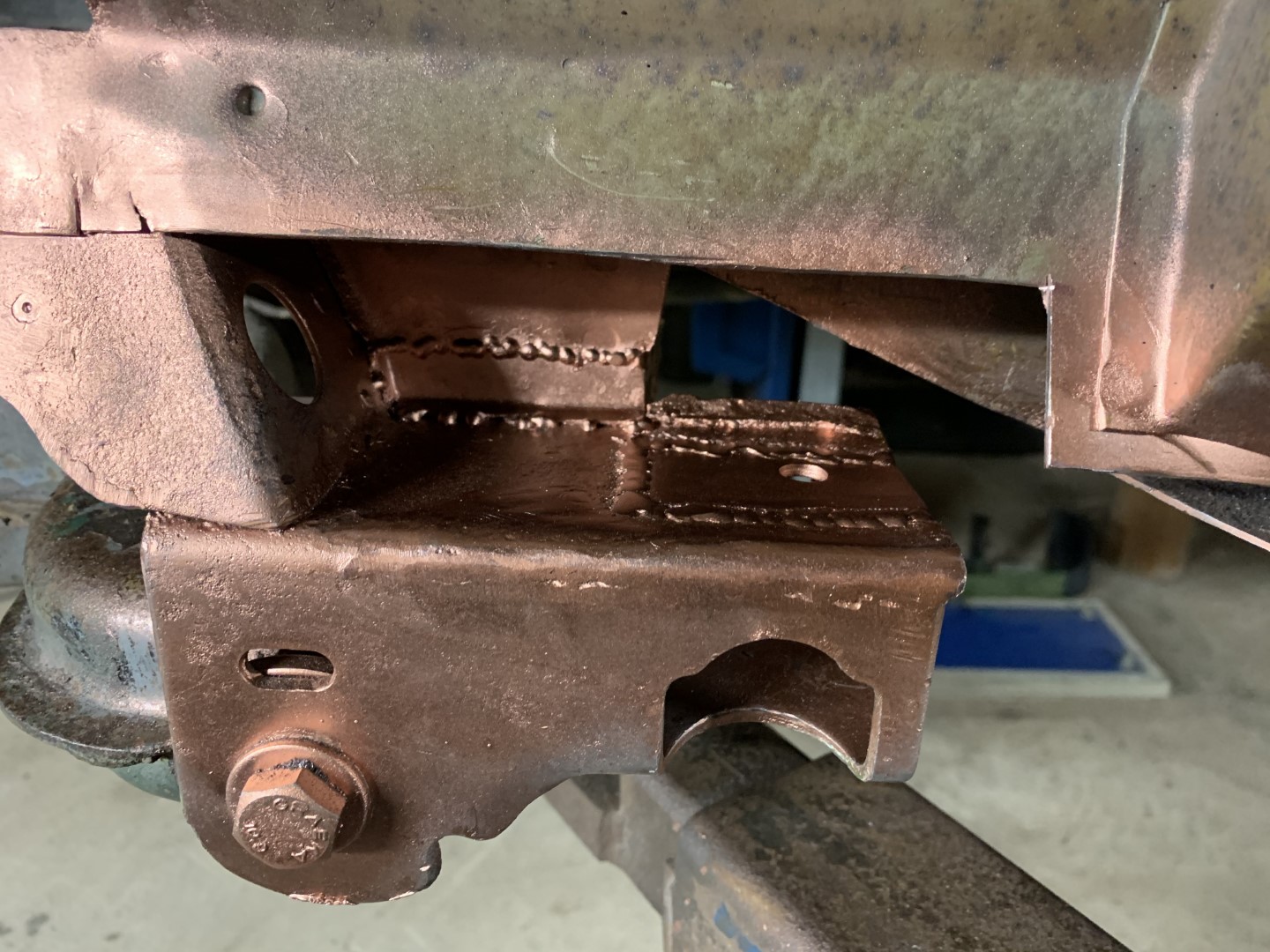

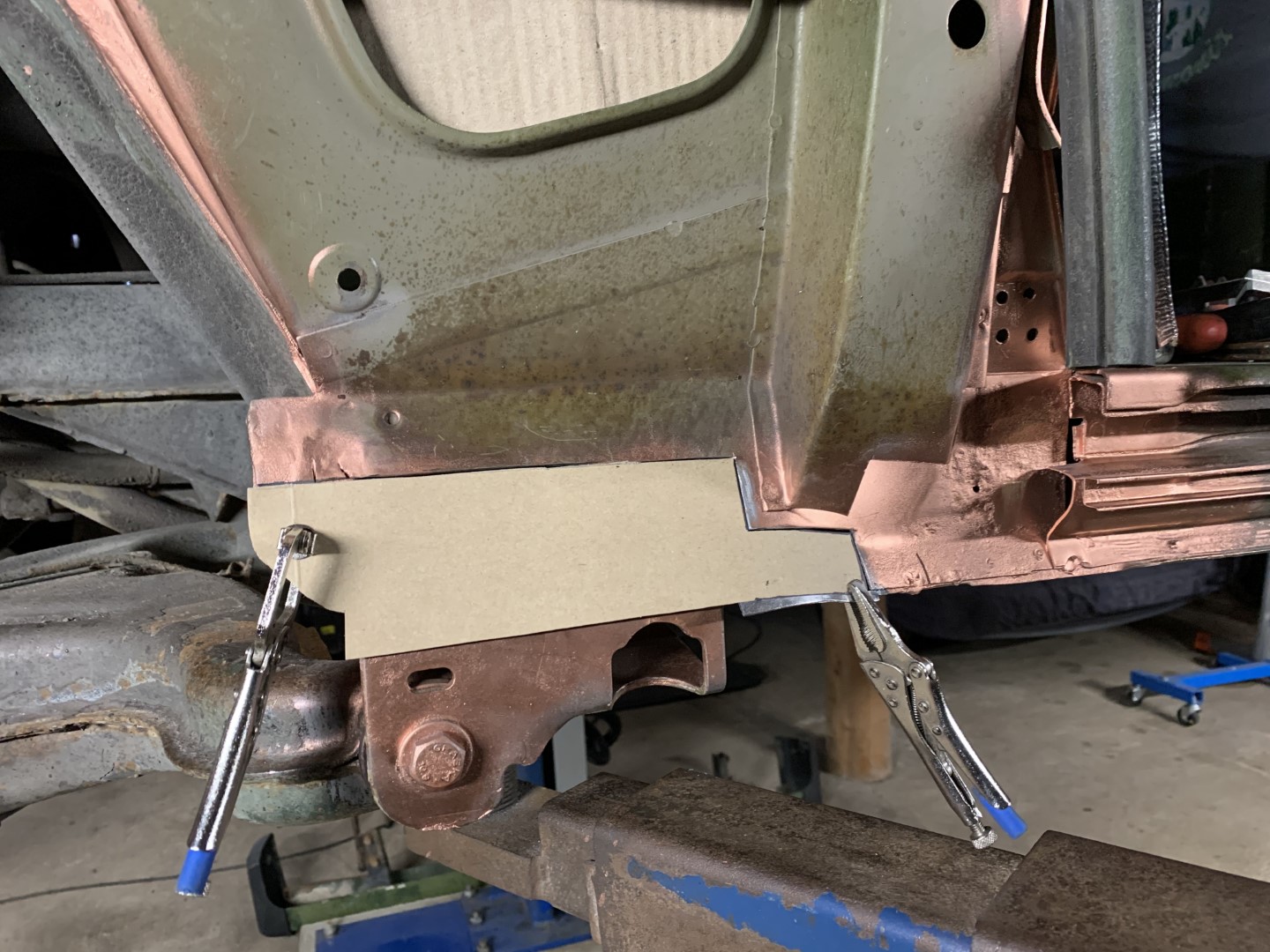

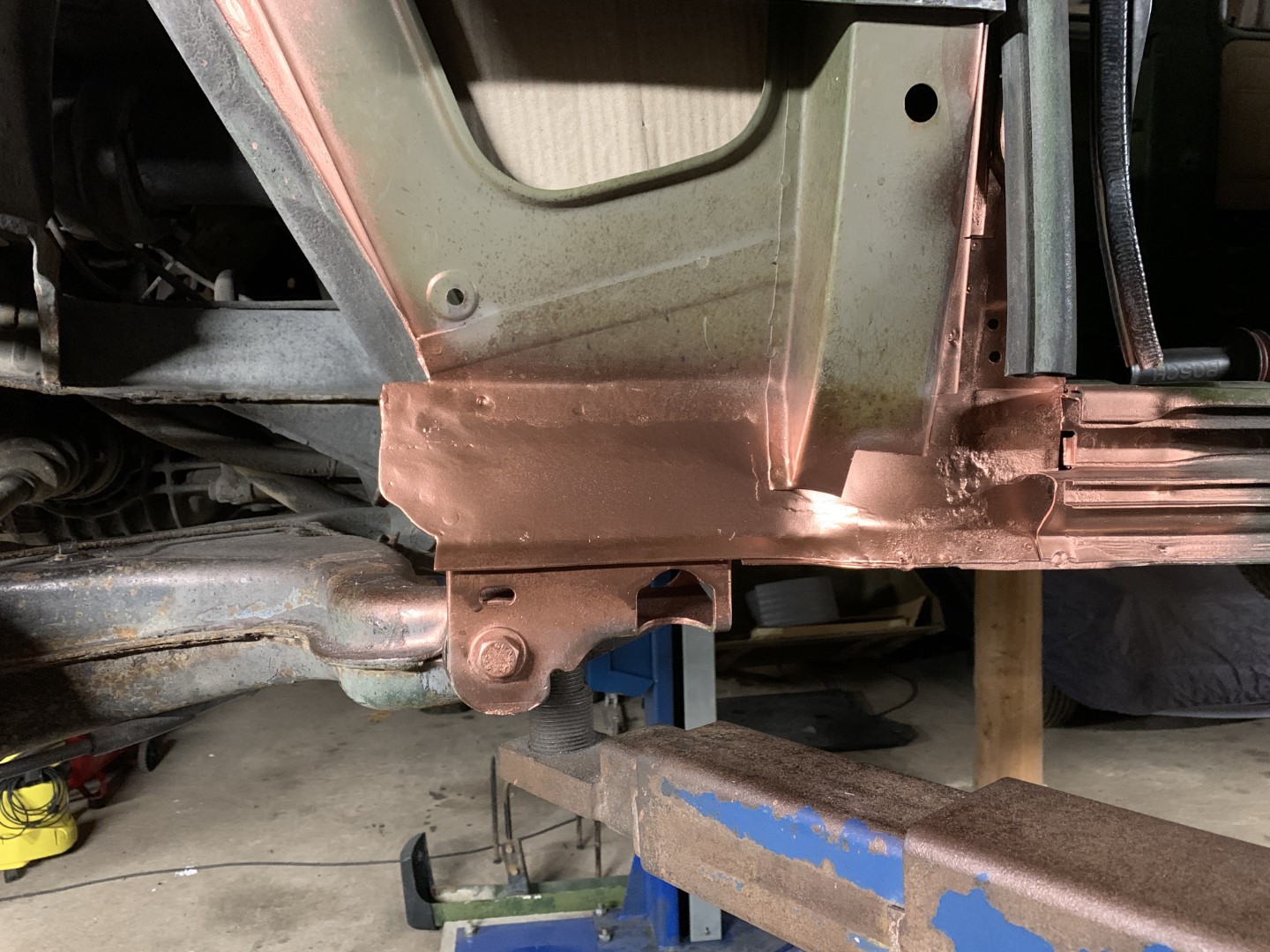

Trailing-arm Mounting Point

When I was mapping the condition of the body for the first time, already then I noticed that the outer trailing-arm mounting point (VW p/n 251 803 198) on the right side is definitely going to need some attention. At first, I tried to stay optimistic and I even believed that maybe I won’t need to cut the “box” all the way open. Boy, was I wrong.

After removing the rusted metal, it no longer seemed as bad as it had before. Since there seemed to be enough metal left that I could weld on, I decided not to get replacement panels for this. Instead I used some plain sheets and crafted the needed pieces myself.

In the next post I will address the repairing of the lower end of the C-pillar and the back corner of the side door raililng. From the new replacement panels I will weld on the lower part of the side panel above the trailing-arm mounting point, lower panel of the D-pillar with the connecting piece between the air guide box and eventually the wheel arch panel as well.

Replacement panels

| Title | VW panel | Replacment panel |

|---|---|---|

| Corner panel | 251 813 368 | AHSchofield repair panel |